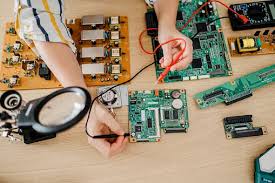

Custom PCB Solutions in India: Tailoring Technology to Your Needs

The Indian PCB industry has witnessed high growth on the fast track; this industry is driven by growing demand for electronic devices in several sectors such as telecommunications, consumer electronics, healthcare, automotive, and others. In 2020, the Indian PCB market totaled approximately USD 2.37 billion and is expected to grow by 17.7% CAGR between 2021 and 2026. This growth is driven by the national impetus to become self-sufficient in manufacturing and the newly developing startup ecosystem. As such, in India, custom PCB solutions have become the order of the day for any business seeking innovation or meeting specific technological requirements.

Evolution of Custom PCB Solutions in India

Custom PCB solutions are not a novel idea, but this has seen significant evolution concerning application and importance in the recent past. Initially, traditional uses of PCB mainly focused on simple electronic gadgets that constituted very minimal functionalities. However, technologies like the IoT, AI, and 5G connectivity have spurred the need for more complex and customized designs.

Importance of Personalized PCB Solutions

A few reasons custom pcb india solutions are important are listed:

- Tailored Design: Custom-designed PCBs enable results that can be tailored to respond to the needs stipulated by a given application, thus yielding improved performance and efficiency.

- Size Optimization: Electronic devices highly demand the compaction and oozing of devices. Custom PCBs cater to this requirement by helping optimize space, not compromising on the working functionality.

- Improved functionalities: A custom design can integrate multiple functionalities on one board, which cuts the need for extra components and streamlines the overall design.

- Cost efficiency: The upfront cost in the customization of a PCB may initially seem outweighed by other options; however, that can turn into long-term savings through minimized material usage, less wastage, and an end product that is highly energy efficient.

How Lion Circuits Helps Custom PCB India

One of the front-running companies, Lioncircuits, for custom or bespoke PCB solutions in India, offers innovative approaches to state-of-the-art manufacturing. Lion circuits provides an end-to-end solution, right from the procurement of the design to the final delivery. Their state-of-the-art manufacturing supports their capability of supplying PCBs to customers with very high conformities to the complex requirements of advanced technologies.

The Process of Developing Custom PCB Solutions

The creation of a custom PCB goes through a variety of steps, every one of which requires concentrated focus, paying minute attention to detail, sounding out the client about their requirements, and understanding and owning the technological landscape entirely. Now, these steps are discussed comprehensively below:

- Requirement Analysis

- The very first stage of any custom PCB development is understanding the client’s requirements, which may include quite detailed discussions to understand particular needs, applications, and constraints. Some of these things to be decided are the intended size, shape, functionality, and environmental conditions under which we expect the board to be working.

- Schematic Design

- With precise requirements, the next step is to develop a schematic design; that is, placing a developed circuit diagram representing connections of electrical components on the PCB. For that, advanced software tools are applied to provide clear and precise schematics, where these schematics would represent the blueprint for the PCB layout.

- Design PCB Layouts

- After the schematic has been generated for the design, the next part of the design process involves designing a PCB layout. In this process, one determines how the schematic elements will fit on a board; it covers the routing of electrical connections and the placement of components. Designing a layout for a PCB affects the PCB’s performance, reliability, and manufacturability. The layout is determined by design for manufacturability (DFM) guidelines to enable the fabrication of the PCB most efficiently and cost-effectively possible.

- Prototype Development

- Before mass production, a prototype of the custom PCB is designed. From here on, the design is validated, and at this point, possible issues are identified. It is tested for compliance with each specified requirement and proper operation. In case it is imperative, the adjustments are brought back according to the comments of the testing phase of the prototype.

- Manufacturing

- After the prototype is approved, the PCB moves through the house in manufacturing. This involves the actual production of PCBs with the use of advanced fabrication processes. The quality check is made at each step in the manufacturing process to ensure the quality and reliability of the highest level for the final product.

- Testing and Validation

- At the end of the process, during custom-made PCB production, each piece goes through thorough testing and validation to confirm its functionality, performance, and reliability, ensuring it works perfectly under various conditions. Any resultant defects are corrected before sending the PCB to the customer.

- Delivery and Support

- The process progresses to the final stage, which is the delivery of the custom PCB to the client. Leading providers, like Lioncircuits, go a notch higher to offer additional support and maintenance services for the same purpose of ensuring that the installed PCB continues to be in its best condition all the way.

Benefits of Custom PCB Solution in India

There are several advantages of working with custom PCB solution providers in India due to the growing PCB industry in India:

- Cost-Effective Manufacturing

- India is adept at cost-effective manufacturing facilities. With skilled labor and world-class facilities for most manufacturing needs, plus policies of government inclined towards welcoming foreign investment and companies, it extends excellent opportunities in manufacturing most items, especially PCBs. Companies can thus benefit from this opportunity and associate it with the chance of having world-class, low-cost PCBs made to order.

- Access to Advanced Technologies

- Indian PCB manufacturers have the state-of-the-art technologies and equipment available at their disposal, enabling them to fabricate advanced and innovative PCB design. It includes high-density interconnect PCBs, flexible PCBs, multilayer PCBs, and such technologies that are imperative for the modern-day electronic devices.

- Strong Ecosystem

- Suppliers, vendors, and service providers in India back the PCB industry with a robust ecosystem. This ensures that all materials, components, and services needed in manufacturing are available on tap, cutting down lead times and improving the overall efficiency of the manufacturing process.

- Customization and Flexibility

- Indian PCB manufacturers are known for their flexibility and accommodation of special requirements. Close stakeholder engagement is emphasized to understand special needs, which can be developed from custom-made solutions to meet those requirements. This level of customization is critical to companies developing innovations and differentiators in their products to compete in the market effectively.

- Focus on Quality

- Quality is a very significant concern for manufacturers of PCBs in India. They conform to international quality standards and inculcate at each manufacturing step high measures of quality control to proclaim the final product as reliable, durable, and of high standards of performance.

Case Studies: Successful Implementation of Custom PCB Solution in India

Case Study 1: Custom PCB for Healthcare Equipment

A leading healthcare company approached Lioncircuits looking for a solution for a custom PCB for their new product range concerning the advances in medical technology. They needed hardware miniaturization, and very high reliability, with most functionalities integrated onto a single board. Lioncircuits engineered the custom-made PCB to every specification, and after being passed through heavy testing and validation by the company, the result was a compact, reliable, and high-performance PCB. The result allowed a healthcare company to be on time for its new medical devices’ launch.

Case Study 2: Application Of Custom Designed PCB In IoT

An IoT startup contacted Lion circuits about a custom requirement of packing features into PCBs for his smart home devices, compact, power-saving, and wirelessly enabled. Lioncircuits quickly designed and fabricated a custom PCB that satisfied all these requirements, including Wi-Fi and Bluetooth modules’ integration into their smart home device application. The startup thus could take their product to launch primarily because of the quality of custom PCBs supplied by Lioncircuits.

The Future of Custom PCB Solutions in India

Key trends which are driving the future of custom PCB solutions in India:

- Growing Demand for Advanced Electronics

- Customized PCBs are bound to have higher demand, with new waves like IoT, AI, and 5G coming through. This will, hence increase the requirement for more advanced technologies that will be supported with customized PCBs.

- Sustainable Manufacturing Focus

- The electronic industry is now focusing on sustainability issues, so PCB manufacturers in India are adopting eco-friendly suppliers and processes to reduce the level of involvement in the degradation of the environment. These comprise lead-free soldering material in the PCB assembly, recycling process implementation of by-products, and intolerance of energy-efficient processing techniques.

- Adoption of Industry 4.0

- The massive transformation in vision within the PCB manufacturing will flow towards the adoption of Industry 4.0 technologies along with automation, robotics, and big data analytics. These technologies make the manufacturing process more efficient, accurate, and swift, hence supporting manufacturers in the production of large volumes of high-quality custom PCBs more efficiently.

- Expansion of Domestic Manufacturing

- The Indian government is looking to provide a fillip to domestic manufacturing through schemes like Make in India and the Production Linked Incentive scheme. This shall provide incentive support for establishing new manufacturing facilities and expanding existing ones, providing a fillip to the PCB industry.

Conclusion

This therefore, places India at a very crucial place in driving innovation with custom PCB solutions and making businesses meet their desired technological needs. Even as demand for advanced electronics goes robust, India is well poised to lead the manufacturing sector of custom PCBs globally due to three key reasons: cost-effective manufacturing, access to advanced technologies, and a robust ecosystem. “It is companies like Lioncircuits that are at the helm of affairs, providing high-quality, customized PCB solutions that aid business in meeting their objectives and being one step ahead in the competitive market.” With industry development changing so rapidly, one can undoubtedly tell that the future of Indian-based custom PCB solutions has great potential both for businesses and manufacturers.